The world of textiles is undergoing a silent revolution, driven by innovations like the water-soluble fiber. While traditional materials have served us well for centuries, the demand for higher performance, greater comfort, and improved sustainability has paved the way for advanced synthetic fibers that are redefining what is possible in manufacturing. These materials are not just threads; they are engineered solutions designed for specific, high-tech applications, from luxury apparel to industrial composites, pushing the boundaries of design and functionality.

### Understanding Water-Soluble Materials in Textiles

At the forefront of this innovation are water-soluble materials. In essence, these are temporary structural components used during the manufacturing of textiles. A prime example of this technology is PVA fiber (polyvinyl alcohol), which dissolves completely in water under specific temperature conditions. This unique property allows it to be used as a sacrificial or carrier fiber. It provides support and structure while weaving or knitting complex fabrics, and once its job is done, it is simply washed away, leaving behind an intricately designed final product without the need for harsh chemicals or complicated mechanical processes. This method is instrumental in creating lightweight, delicate, or highly porous textiles that would otherwise be impossible to produce.

### The Intricacies of Island Fiber Technology

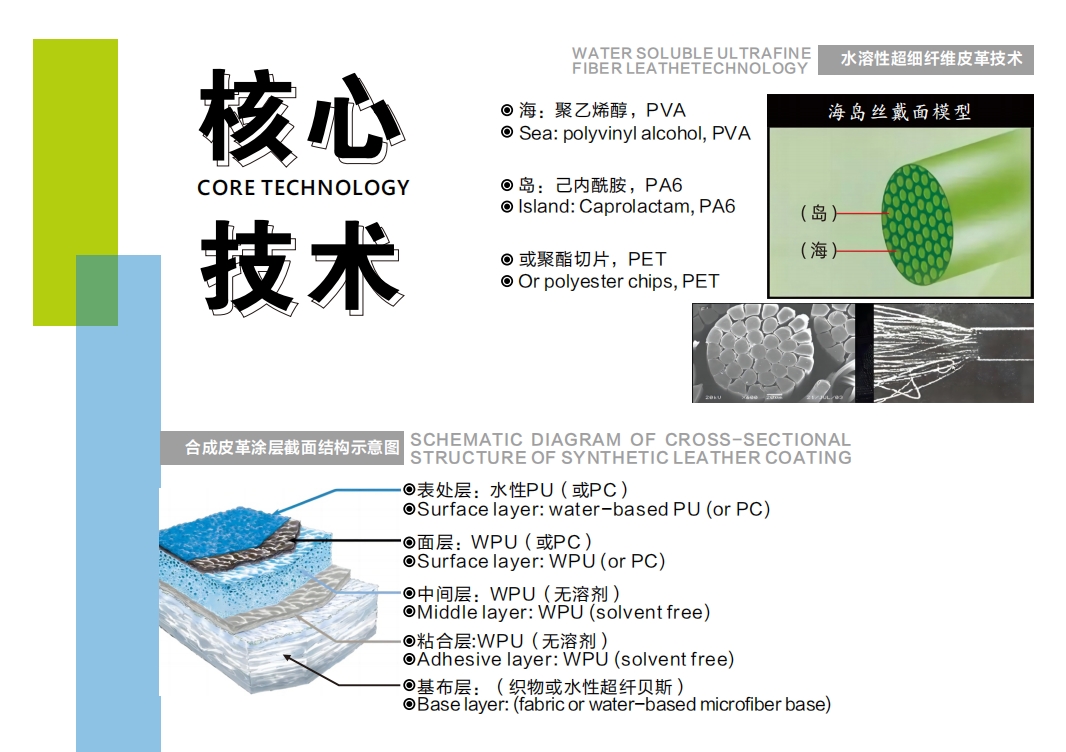

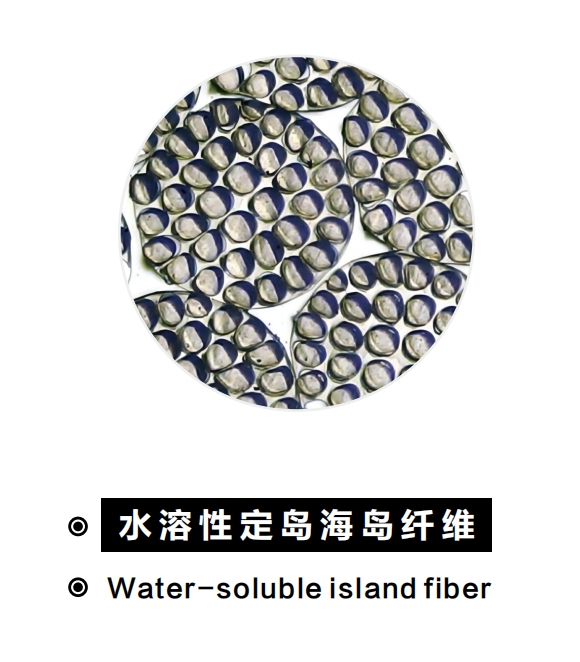

The most sophisticated application of this technology is arguably the creation of island fiber. This composite fiber features a unique “sea-and-island” cross-section, where multiple ultra-fine filaments (the “islands”) are embedded within a soluble polymer matrix (the “sea”). The sea component is typically a water-soluble fiber like PVA fiber, while the islands can be made from high-performance polymers such as PA6 fiber (Nylon 6). After the fabric is constructed, it undergoes a washing process where the “sea” polymer dissolves, leaving behind only the clusters of extremely fine island filaments. This process results in fabrics with an incredibly soft handle, high density, and a luxurious feel, making island fiber the gold standard for producing high-quality artificial suede and other premium textiles.

### Innovations Across the Spectrum of Synthetic Fibers

Beyond the intricate world of dissolvable polymers, innovation is rampant across the broader spectrum of synthetic fibers. Manufacturers are engineering fibers with specific physical properties to meet consumer demands for both comfort and performance. For example, advanced crimping techniques create spiral-like structures in fibers that deliver exceptional loft, resilience, and thermal insulation. This structure traps air effectively while remaining lightweight and durable, making it an ideal fill material for high-performance jackets, bedding, and pillows. These modern synthetic fibers offer a combination of softness, durability, and functionality that continues to evolve.

### The Eco-Conscious Shift to Biodegradable Fibers

Alongside performance, sustainability has become a critical focus in textile development. The use of a water-soluble fiber in manufacturing is inherently eco-friendlier, as it can reduce waste and simplify production. Looking further ahead, the industry is increasingly focused on the entire lifecycle of a product, leading to a surge in demand for biodegradable fibers. These materials are engineered to break down naturally at the end of their useful life, minimizing their environmental impact. This shift represents a commitment to circular economy principles, where materials are not only functional and beautiful but also responsible, ensuring that the innovations of today do not become the waste problems of tomorrow.

### The Future is Woven with Smart Fibers

In conclusion, the advancements in textile technology, from the precision of island fiber to the eco-conscious design of biodegradable fibers, are shaping a new era of materials. The strategic use of water-soluble fiber has unlocked new possibilities in fabric engineering, enabling the creation of materials that are softer, stronger, and more specialized. As these technologies continue to mature, they promise to deliver products that seamlessly blend high performance with environmental stewardship, meeting the complex needs of modern consumers and industries alike.

Innovative Uses of Water-Soluble Fiber in Textiles

- blog

100% Merino Wool Yarn: The Perfect Fiber Choice

1.Experience the Unmatched Quality of Luxury Wool Yarn 2.The Perfect Fiber for Knitting and Crocheting 3.Our Commitment to Quality and Ethical Sourcing

Discover the Luxury of 100% Merino Wool Yarn

1.The Unparalleled Elegance of Merino Wool 2.Experience Unmatched Softness and Quality 3.The Perfect Choice for Every Knitting Project 4.Sourcing Your Premium Yarn with CChjang

Nylon Fiber: Versatile and Innovative Textiles

1.Exploring the Versatility of Nylon Fiber 2.Innovative Variations in Nylon Textiles 3.Ningbo Sinopec Fiber Co., Ltd.: Pioneering Nylon Fiber Manufacturing 4.The Advantages of Synthetic Fibers

Elevate Your Wardrobe with Timeless Clothes

1. Elevate Your Wardrobe with Timeless Clothes 2. The Allure of Olive Green 3. Chic Yet Cozy Knitwear 4. Mix-and-Match Versatility 5. Quality Craftsmanship 6. The Ningbo Sinopec Fiber Co., Ltd. Experience

Explore Luxury with 100% Merino Wool Yarn for Knitting

1. Discover the Elegance of 100% Merino Wool Yarn 2. Why Choose Pure Merino Wool for Your Projects? 3. Where to Buy Merino Wool Yarn and Knitting Supplies 4. Transform Your Creations with Merino Wool

Discover the Beauty and Benefits of 100% Merino Wool Yarn

1.Discover the Beauty of 100% Merino Wool Yarn 2.The Irresistible Benefits of Merino Wool Yarn 3.Why Choosing Merino Wool Yarn is Worth It 4.Make Your Knitting Projects Stand Out