In the vast world of modern materials, few have had the transformative impact of Nylon 6. As a cornerstone among synthetic fibers, this remarkable polymer has woven itself into the fabric of our daily lives and industries, offering a unique combination of strength, durability, and versatility. Its invention marked a significant leap forward in material science, providing a cost-effective and highly adaptable alternative to natural fibers and metals. Whether you are a product designer, an engineer, or simply curious about the materials that shape our world, understanding the power of this specific nylon variant is essential for appreciating modern manufacturing and innovation.

Unpacking the Remarkable Nylon 6 Properties

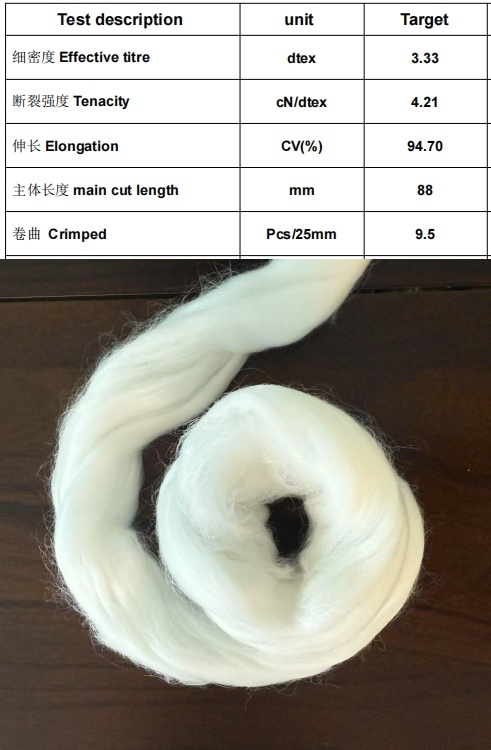

What truly sets this material apart is its incredible array of beneficial characteristics. A deep dive into the Nylon 6 properties reveals why it has become such an indispensable resource. First and foremost is its exceptional tensile strength and toughness, allowing it to withstand significant stress and wear without failing. It possesses excellent elasticity, meaning it can stretch and return to its original shape, a feature crucial for textiles and flexible components. Furthermore, it exhibits high resistance to abrasion, making it ideal for high-contact applications like carpeting, upholstery, and industrial bearings. It is also resistant to many chemicals, oils, and fungi, ensuring longevity and reliability even in harsh environments. This powerful combination of features ensures that products made from it are not only strong but also incredibly resilient and long-lasting.

The Unmatched Strength of High Tenacity Nylon

For applications that demand even greater performance, engineers and manufacturers turn to high tenacity Nylon. This specialized grade is engineered through a process of high-ratio drawing, which aligns the polymer chains to create a fiber with an exceptionally high strength-to-weight ratio. This enhancement makes it a superior choice for some of the most demanding tasks imaginable. You will find this robust material in critical components like automotive tire cords, where it provides structural integrity and safety at high speeds. It is also the material of choice for industrial ropes, seatbelts, parachutes, and heavy-duty conveyor belts, where failure is not an option. The development of this high-strength variant showcases the continuous innovation within the field of synthetic fibers and expands the possibilities for creating safer, more durable products.

Exploring the Diverse Nylon 6 Applications

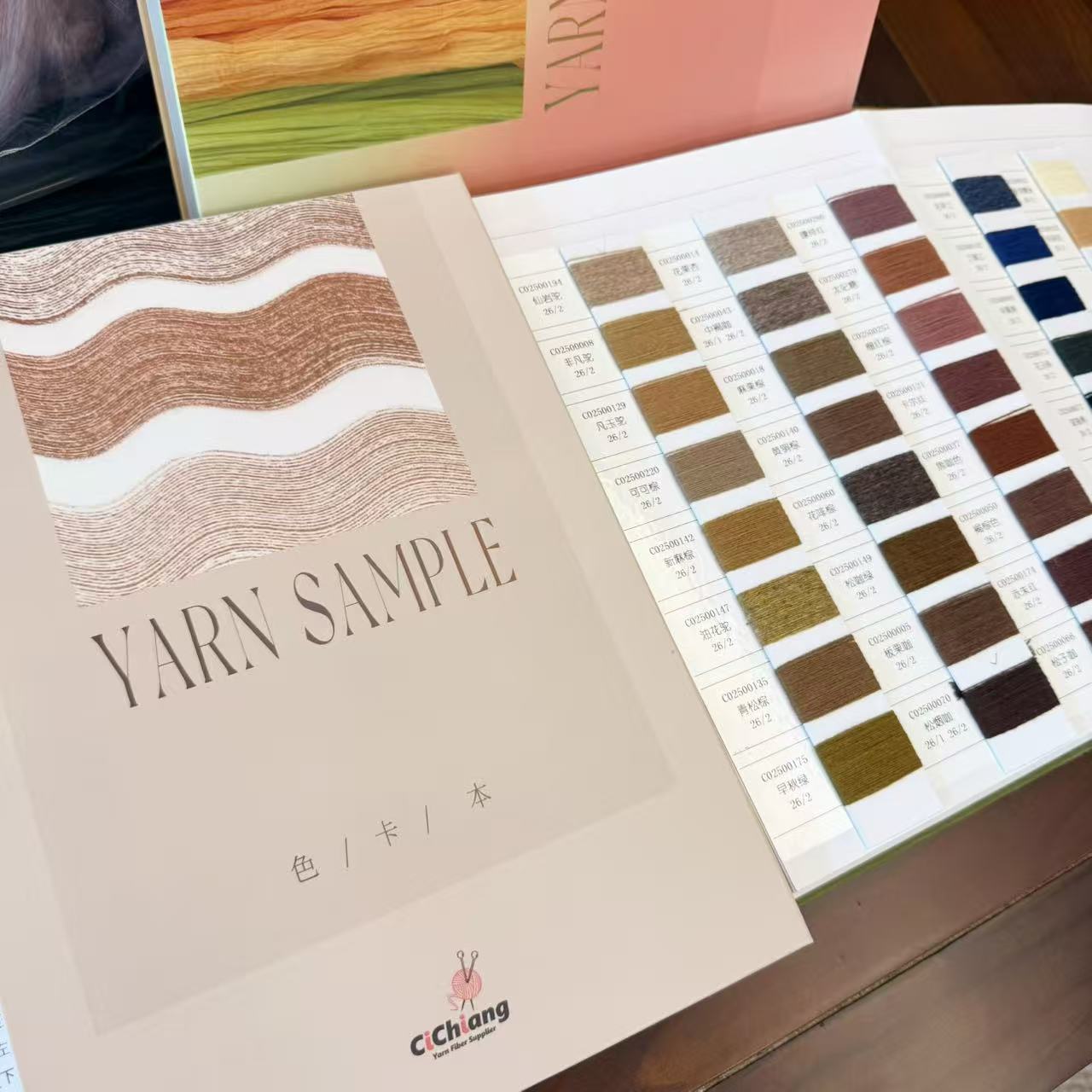

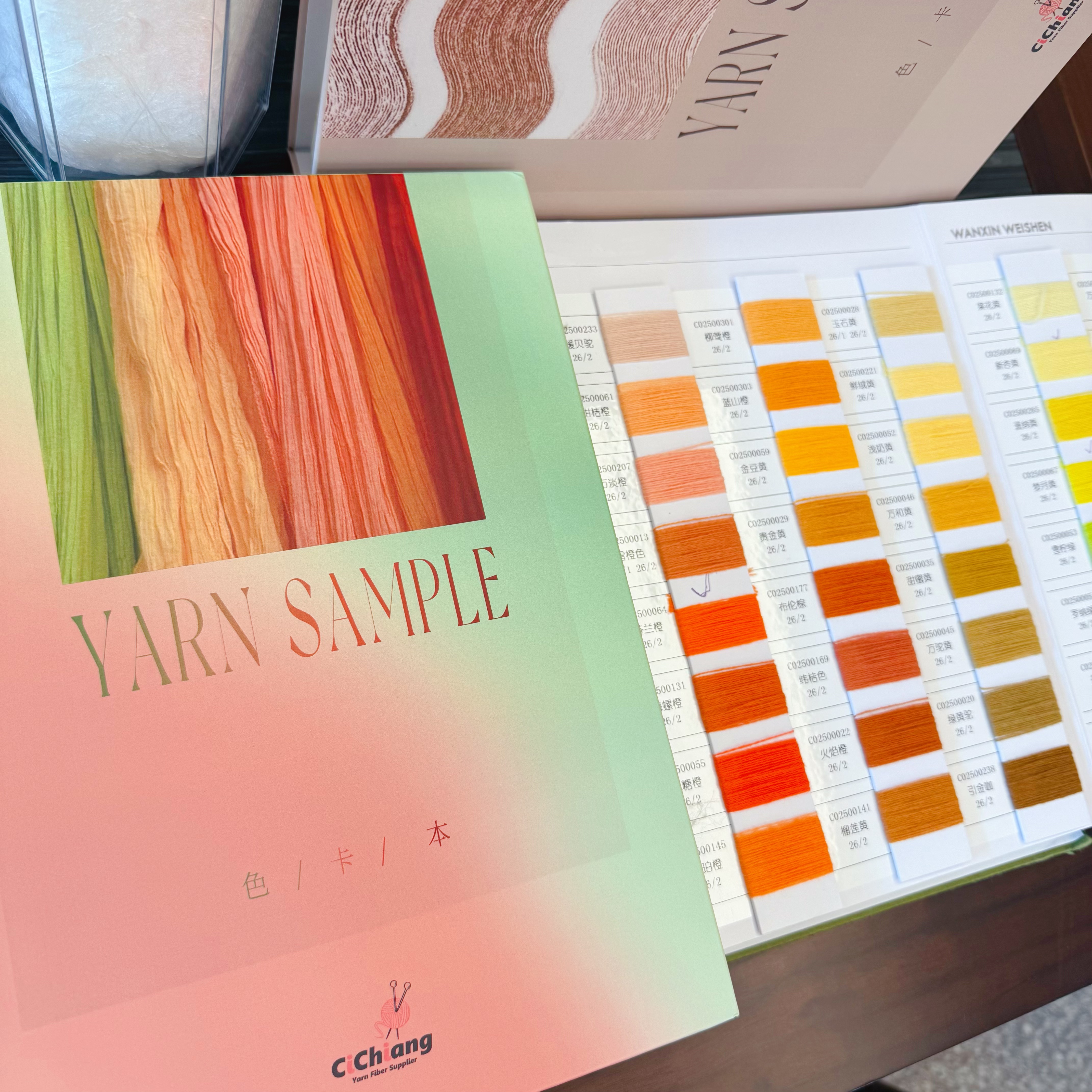

The sheer scope of Nylon 6 applications is a testament to its adaptability. In the textile industry, its fine, smooth filaments are used to create everything from sheer hosiery and activewear to durable luggage and backpacks. Its ability to accept dyes readily allows for vibrant and long-lasting colors. Beyond apparel, its mechanical strength makes it a preferred material in the automotive sector for engine components, gears, and fuel tanks. In the world of consumer goods, it is found in the bristles of toothbrushes, fishing lines, and various kitchen utensils. Its use in electrical engineering for insulators and connectors highlights its non-conductive properties. This widespread adoption across nearly every industry underscores its value as a multi-purpose, high-performance polymer that consistently delivers results.