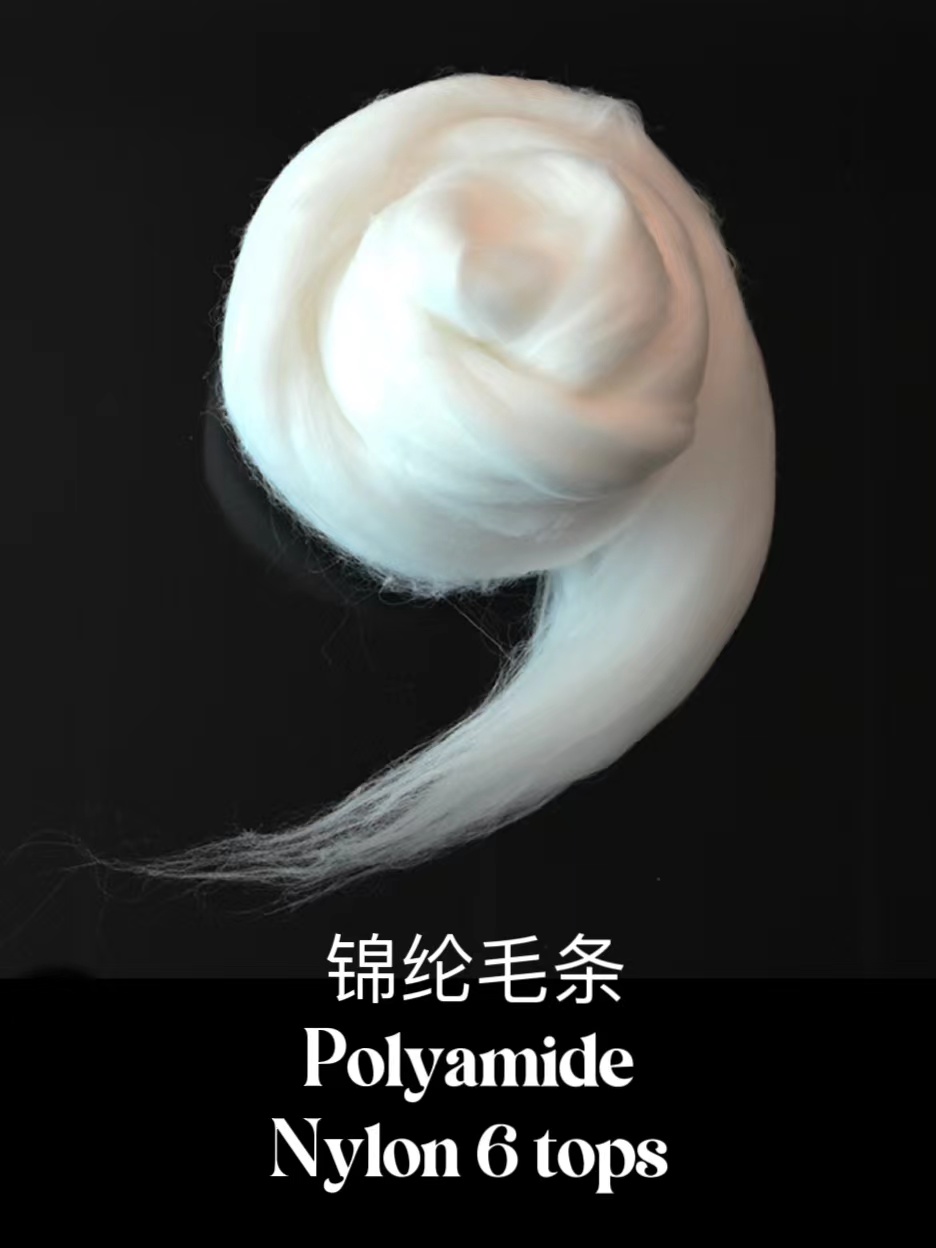

In the vast world of modern materials, Nylon 6 stands out as a remarkably versatile and reliable polymer. As one of the most significant commercial polyamides, this material has revolutionized countless industries since its development. Its unique combination of strength, flexibility, and durability makes it an indispensable choice for engineers, designers, and manufacturers across the globe. Whether you are looking for a fiber for textiles or a robust plastic for mechanical parts, Nylon 6 offers a compelling solution that balances performance with economic viability, setting it apart from other synthetic fibers.

Understanding the Core Nylon 6 Properties

The impressive performance of this material is rooted in its fundamental Nylon 6 properties. It exhibits exceptional tensile strength and elasticity, meaning it can stretch significantly without breaking and then return to its original shape. This toughness is complemented by excellent resistance to abrasion, wear, and a wide range of chemicals, including oils and solvents. Furthermore, Nylon 6 is lightweight and has a natural luster, which makes it aesthetically pleasing for consumer products. For applications requiring even greater strength, specialized variants like high tenacity Nylon are developed through advanced processing techniques, pushing the boundaries of what this polymer can achieve.

A Leader Among Synthetic Fibers

When compared to other synthetic fibers, Nylon 6 carves out its own unique niche. While materials like polyester may offer better resistance to UV degradation, Nylon 6 provides superior abrasion resistance and a softer, more comfortable feel, making it a preferred choice for apparel and carpeting. Its excellent dyeability allows for deep, vibrant, and long-lasting colors that are often difficult to achieve with other polymers. This blend of comfort, durability, and aesthetic potential ensures that it remains a dominant force in the textile industry, offering a premium feel that consumers and designers value highly.

Diverse and Demanding Nylon 6 Applications

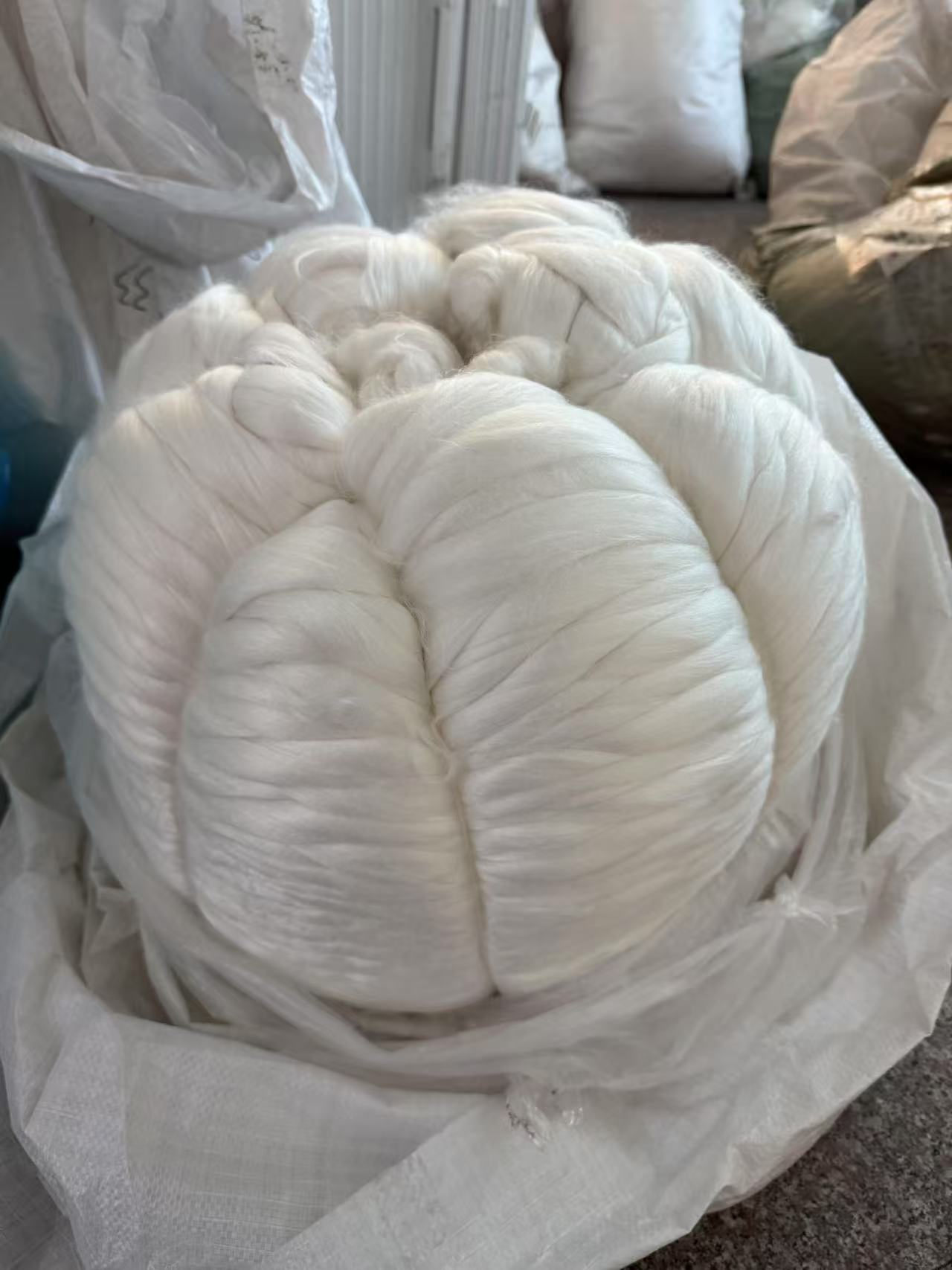

The practical benefits of this polymer translate into a vast array of Nylon 6 applications. In the automotive industry, it is used to create engine covers, air intake manifolds, and gears, where its resistance to heat and chemicals is crucial. The textile world relies on it for everything from hosiery and activewear to luggage and carpets. Furthermore, the exceptional strength of high tenacity Nylon makes it the go-to material for industrial uses such as fishing nets, ropes, tire cords, and even parachutes. Its adaptability means it can be molded into complex shapes for electrical connectors and machine parts or spun into fine threads for delicate fabrics, showcasing its incredible range.

Ultimately, the combination of excellent mechanical properties, processability, and cost-effectiveness solidifies Nylon 6's position as a cornerstone of modern manufacturing. Its ability to be tailored to meet specific performance requirements—from everyday apparel to critical industrial components—demonstrates its unmatched value. By choosing this proven material, you are investing in a legacy of innovation and reliability that delivers consistent, high-quality results for the most demanding projects. It is more than just a plastic; it is an engine for progress across countless fields.