When searching for a material that seamlessly blends strength, beauty, and remarkable adaptability, few can rival the performance of Nylon 6. This incredible material has established itself as a cornerstone in both industrial and creative fields, offering a unique combination of resilience and aesthetic appeal. Whether you are an engineer designing a high-performance component or an artisan crafting a bespoke textile piece, understanding the value of this polymer is key to unlocking new possibilities. Its journey from a lab innovation to a globally utilized material is a testament to its superior qualities and its ability to meet the ever-evolving demands of modern manufacturing and design.

Unveiling the Superior Nylon 6 Properties

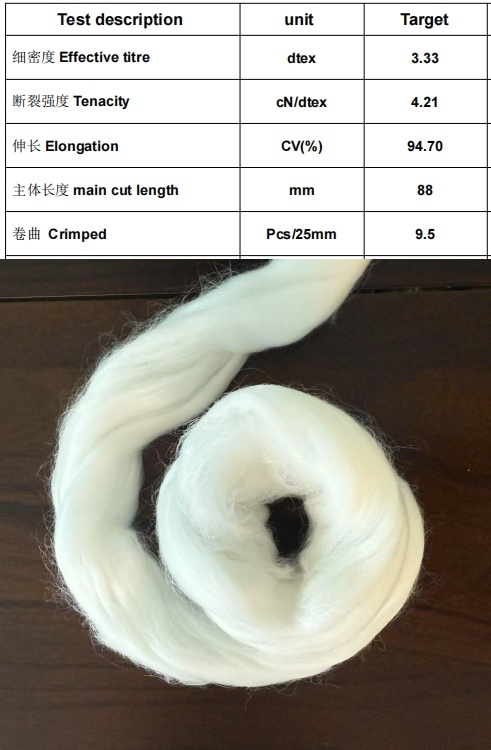

To truly appreciate this material, one must explore the exceptional Nylon 6 properties that set it apart. At its core, it is a polyamide known for its incredible toughness, fatigue resistance, and durability. It boasts a high tensile strength and elasticity, meaning it can stretch without breaking and return to its original shape, making it ideal for items that endure repeated stress. Furthermore, it exhibits excellent resistance to abrasion, impact, and a wide range of chemicals. Beyond these functional benefits, premium grades of Nylon 6 offer a luxurious experience; imagine a pristine white fiber with a delicate, soft texture and a natural sheen. This uniformity and smoothness make it a pleasure to handle and promise consistent, high-quality results in any project.

The Power of High Tenacity Nylon

For applications demanding the utmost in strength and reliability, high tenacity Nylon is the ultimate choice. This specialized variant is engineered to possess an even greater resistance to breaking under tension, making it a critical component in safety and performance-driven products. The manufacturing process aligns the polymer chains more effectively, significantly boosting its load-bearing capacity. This makes high tenacity Nylon indispensable for products like automotive tire cords, heavy-duty ropes, seatbelts, and industrial webbing. Its ability to withstand extreme conditions without failing provides a level of security and longevity that other fibers simply cannot match, solidifying its role in industries where performance is non-negotiable.

A Cornerstone Among Synthetic Fibers

In the vast and competitive world of synthetic fibers, Nylon 6 has carved out a prestigious and enduring position. While other polymers like polyester offer their own advantages, this material provides a unique balance of softness and ruggedness. It bridges the gap between purely functional fibers and those prized for their feel and appearance. As one of the pioneering synthetic fibers, it revolutionized the textile industry, offering a durable, lightweight, and easy-to-care-for alternative to natural materials like silk and cotton. Today, its continuous innovation ensures its relevance, providing solutions that are both practical for everyday use and sophisticated enough for high-end applications.

Exploring Versatile Nylon 6 Applications

The impressive characteristics of this polymer translate into an incredibly diverse range of Nylon 6 applications. In the industrial sector, it is molded into robust machine parts, gears, and electrical components. In the consumer market, it is found in everything from durable luggage and carpets to high-performance athletic wear. However, its potential extends beautifully into the world of artisanal crafts. A high-quality fiber roll of this material is a dream for spinners, weavers, and felters. Its pristine white color provides a perfect canvas for dyeing, allowing for customized, vibrant creations. The smooth, consistent fibers spin into exquisite yarn or can be felted into intricate masterpieces, proving that the robust nature of this material coexists perfectly with elegance and creative expression.