Discovering the Innovation of Core Spun Yarn

In the ever-evolving world of the textile industry, core spun yarn stands out as a revolutionary material that combines durability with comfort. This innovative yarn, featuring a core of synthetic fibers wrapped in softer outer layers, is designed to enhance both strength and flexibility in fabric production. At Ningbo Sinopec Fiber Co., Ltd., we take pride in our expertise in nylon fiber manufacturing, and our NSF Core Spun Yarn exemplifies this commitment. With a blend of 50% Viscose, 28% PBT, and 22% Nylon, this premium product under code W042/48 delivers exceptional performance for high-quality garments.

The Art of Yarn Manufacturing and Spinning Techniques

Yarn manufacturing has come a long way, and core spun yarn represents a pinnacle of advanced spinning techniques. This process involves encasing a strong core, often made from synthetic fibers like nylon, with a sheath of natural or blended fibers for a soft touch. In the textile industry, such innovations are crucial for creating yarns that withstand wear while feeling luxurious against the skin. Our company, founded in 1996, has honed these techniques over decades, producing PA6 and PA66 polyamide nylon fibers with a daily output of 100-150 tons. Whether for knitting yarn or weaving yarn, core spun yarn ensures that fabrics maintain their shape and elasticity, making it ideal for everything from apparel to upholstery.

Versatility of Synthetic Fibers in Core Spun Yarn

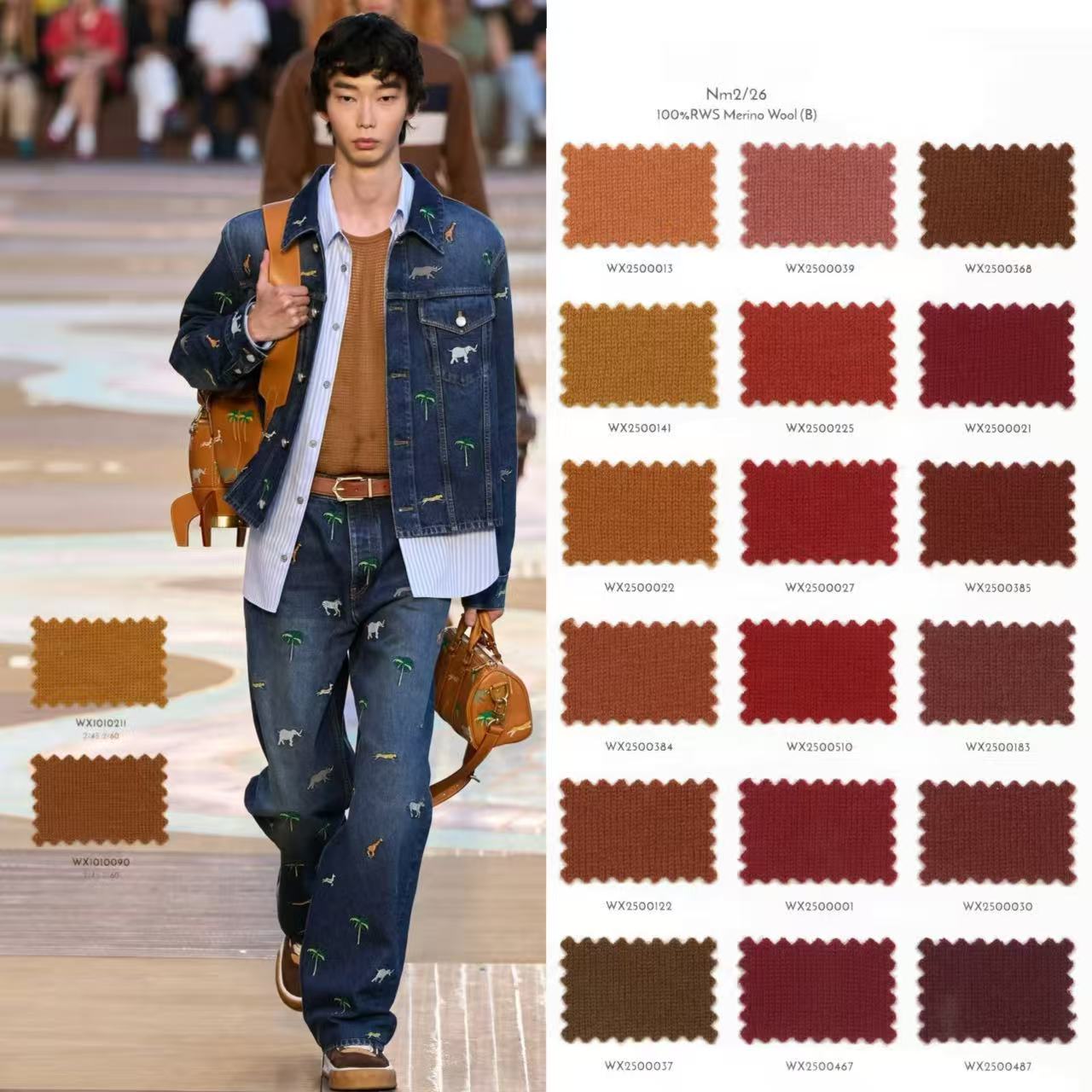

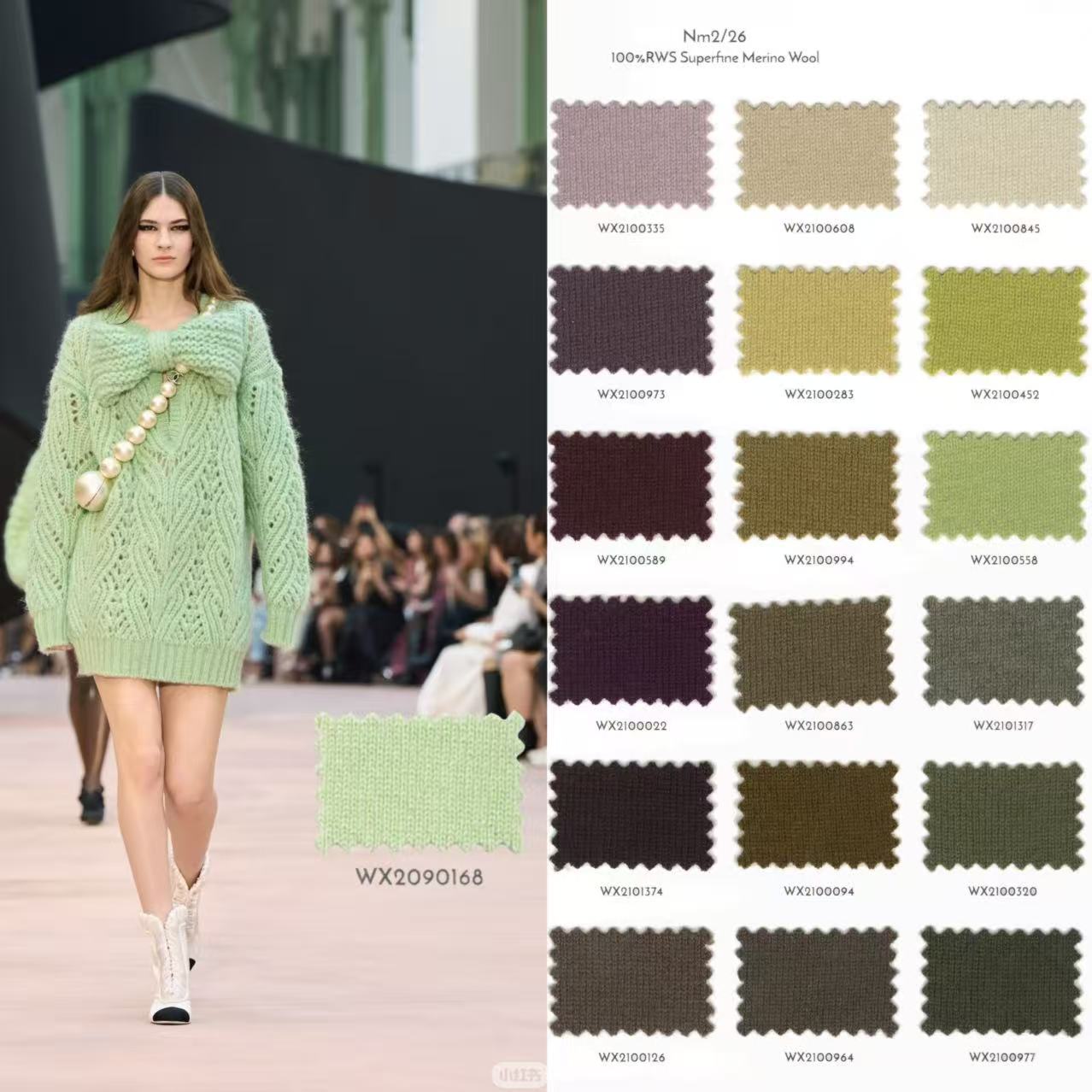

Synthetic fibers play a starring role in the composition of core spun yarn, providing the resilience needed for demanding applications. By integrating materials like PBT and Nylon, this yarn achieves superior stretch and recovery, which is particularly valuable in the production of knitting yarn for activewear or weaving yarn for durable home textiles. Ningbo Sinopec Fiber Co., Ltd., with our 50,000 square meter facility and team of 20 engineers, focuses on quality control to ensure each strand meets rigorous standards. The result is a yarn that not only boosts the longevity of products but also offers a wide array of 400 vibrant colors, from rich reds to subtle pastels, allowing designers endless creative freedom.

Applications in Knitting Yarn and Weaving Yarn

When it comes to practical use, core spun yarn shines in both knitting yarn and weaving yarn projects. For knitters, its high elasticity prevents sagging and ensures a comfortable fit, while weavers appreciate how it holds intricate patterns without fraying. In the textile industry, this yarn is transforming fashion and interior design, enabling the creation of stunning swatches and color palettes that inspire innovation. Our High Elastic Core Spun Yarn collection, for instance, is meticulously crafted to cater to professionals seeking versatility. With tassels, fabric samples, and even complementary paint options in our toolkit, Ningbo Sinopec Fiber Co., Ltd. supports creators in weaving together textures and tones for balanced, visually appealing spaces.

Elevating Your Textile Creations with Quality Assurance

At the heart of our operations, core spun yarn is more than just a product—it's a partnership in excellence. With 150 dedicated employees across 20,000 square meters of production space, we invite long-term collaborations to bring your visions to life. This yarn's blend of strength and softness makes it perfect for elevating crafting experiences, whether you're a designer matching hues from our extensive color chart or a manufacturer prioritizing durability. By choosing our core spun yarn, you invest in a material that harmonizes functionality with aesthetics, pushing the boundaries of what's possible in yarn manufacturing and beyond. Explore how this innovative solution can enhance your next project today.