In the vast world of modern materials, few have made an impact as profound as Nylon 6. This remarkable polymer stands as a pillar among synthetic fibers, offering a unique combination of strength, durability, and versatility that has revolutionized countless industries. Since its development, it has become a go-to material for engineers, designers, and manufacturers seeking high-performance solutions for both everyday products and highly specialized equipment. Its adaptability and reliable performance make it a cornerstone of modern manufacturing.

Unpacking the Remarkable Properties of Nylon 6

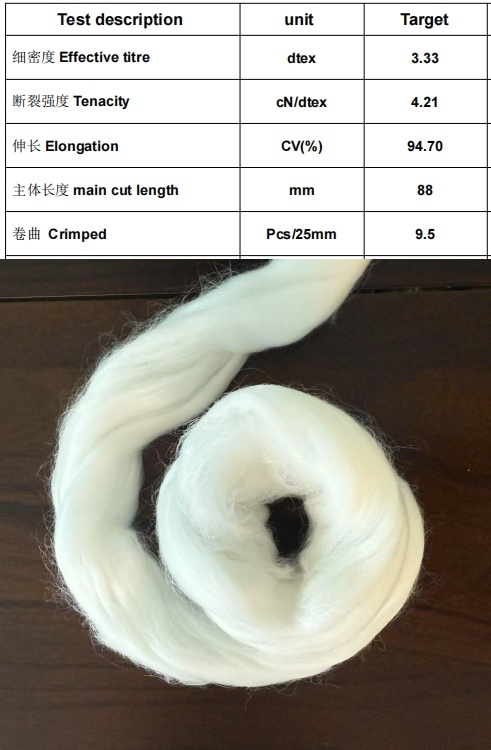

At the heart of its widespread use are the exceptional Nylon 6 properties. This material is renowned for its impressive tensile strength and elasticity, allowing it to withstand significant stress and return to its original shape. This makes it an ideal candidate for products that require resilience and longevity. Furthermore, its excellent resistance to abrasion, wear, and a wide range of chemicals, including oils and alkalis, ensures its integrity even in harsh environments. When engineered for maximum performance, it becomes a high tenacity Nylon, capable of replacing metal components in certain applications, thereby reducing weight and cost without sacrificing durability. This unique blend of characteristics makes it one of the most valuable engineered plastics available today.

Diverse Applications of Nylon 6

The incredible versatility of this polymer is best illustrated by the sheer breadth of Nylon 6 applications. In the textile industry, it is spun into fibers for everything from durable carpets and upholstery to high-performance athletic wear and weather-resistant apparel. Its industrial uses are even more extensive. You will find Nylon 6 in automotive components like engine covers and gears, electrical insulators, and power tool housings. Its strength and low friction coefficient make it perfect for creating durable ropes, fishing lines, and mechanical bearings. The sheer range of applications demonstrates how its core properties can be tailored to meet very specific and demanding requirements across different sectors.

Why Choose Nylon 6 for Your Needs?

When selecting a material, the choice often comes down to performance, reliability, and value. As one of the leading synthetic fibers, Nylon 6 consistently delivers on all fronts. Its manufacturing process is efficient, making it a cost-effective alternative to other materials without compromising on quality. The ability to create high tenacity Nylon variants further expands its potential, pushing the boundaries of what plastic composites can achieve. Whether you are developing consumer goods or industrial machinery, the proven track record and outstanding Nylon 6 properties provide a foundation for innovation and success. Choosing this advanced polymer is an investment in quality, durability, and performance that will stand the test of time.