When exploring the world of synthetic textiles, a common point of confusion is the comparison of polyamide vs nylon. The truth is, these terms are often used to describe the same material. Polyamide is the broader chemical family of polymers, while nylon is a specific type of synthetic polyamide, and the most famous one at that. Understanding this distinction is key to appreciating the versatility and performance of this remarkable material. As specialists in nylon fiber manufacturing since 1996, we at Ningbo Sinopec Fiber Co., Ltd. have dedicated ourselves to mastering the production of high-quality polyamide fibers that serve a vast array of industries, particularly in creating textiles that blend durability with a luxurious feel, such as those found in cashmere blends.

The Science Behind Polyamide Yarn

At its core, polyamide yarn is celebrated for its exceptional strength, elasticity, and abrasion resistance. These properties make it an ideal choice for applications demanding longevity and performance. Our primary products, PA6 and PA66, are two of the most widely used types of polyamide. The chemical structure of these fibers gives them a unique resilience that allows fabrics to retain their shape, resist pilling, and withstand significant wear and tear. This durability does not come at the expense of comfort. Modern manufacturing techniques allow for the creation of incredibly fine and smooth polyamide yarn, which serves as the foundation for everything from high-performance athletic wear to silky, delicate hosiery and sophisticated apparel.

The Unmatched Versatility of Nylon Fiber

The applications for nylon fiber are nearly limitless due to its adaptable nature. Its high tensile strength and ability to be melt-spun into fine filaments make it a cornerstone of the textile industry. From apparel and home furnishings to industrial uses like ropes and carpets, nylon fiber provides a reliable and cost-effective solution. At Ningbo Sinopec Fiber Co., Ltd., our extensive 20,000 square meter production facility allows us to produce 100-150 tons of fiber daily, meeting the diverse needs of our partners. This consistent output ensures that designers and manufacturers have access to a premium material that enhances the quality and lifespan of their final products, proving its value time and time again.

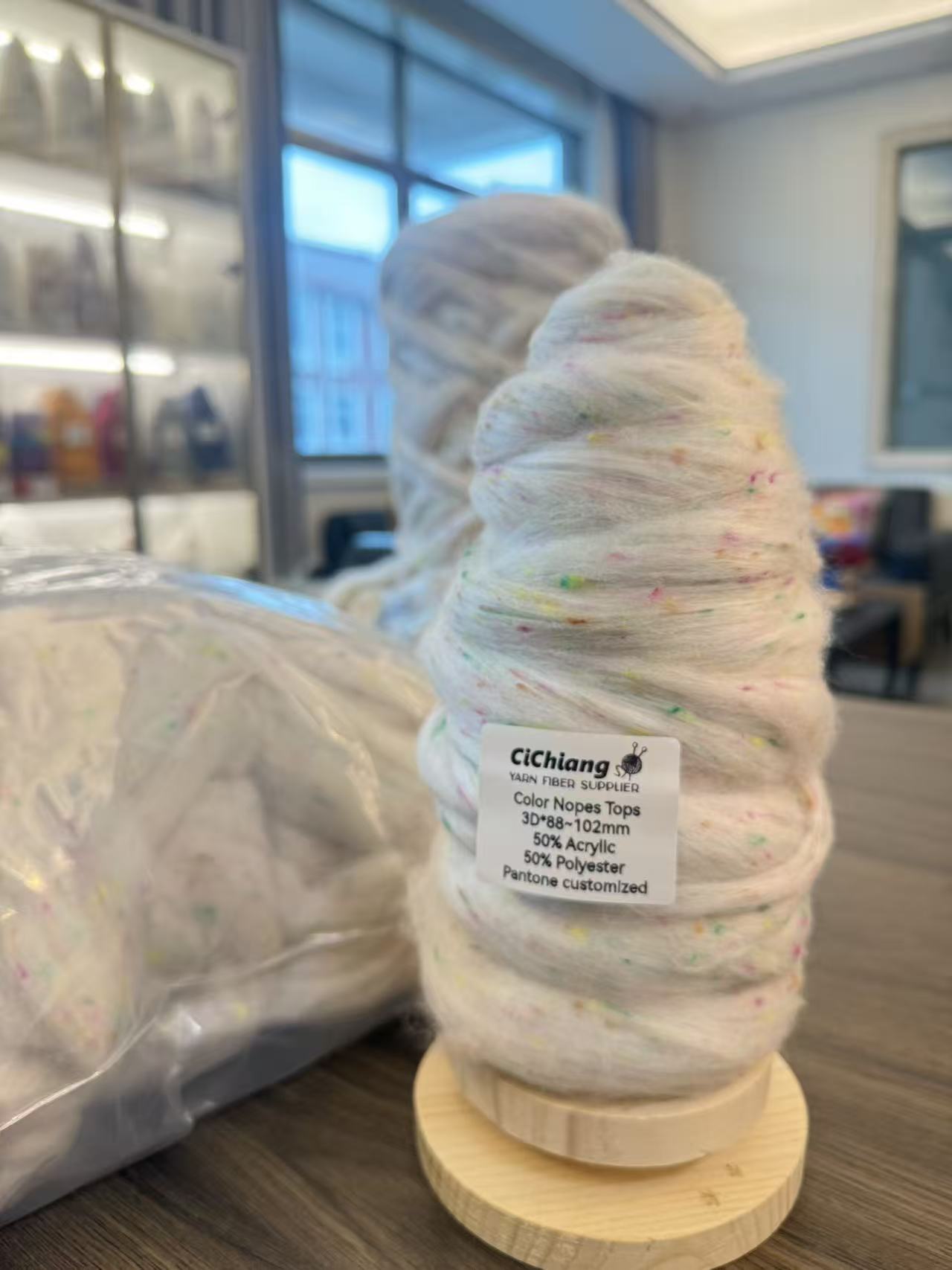

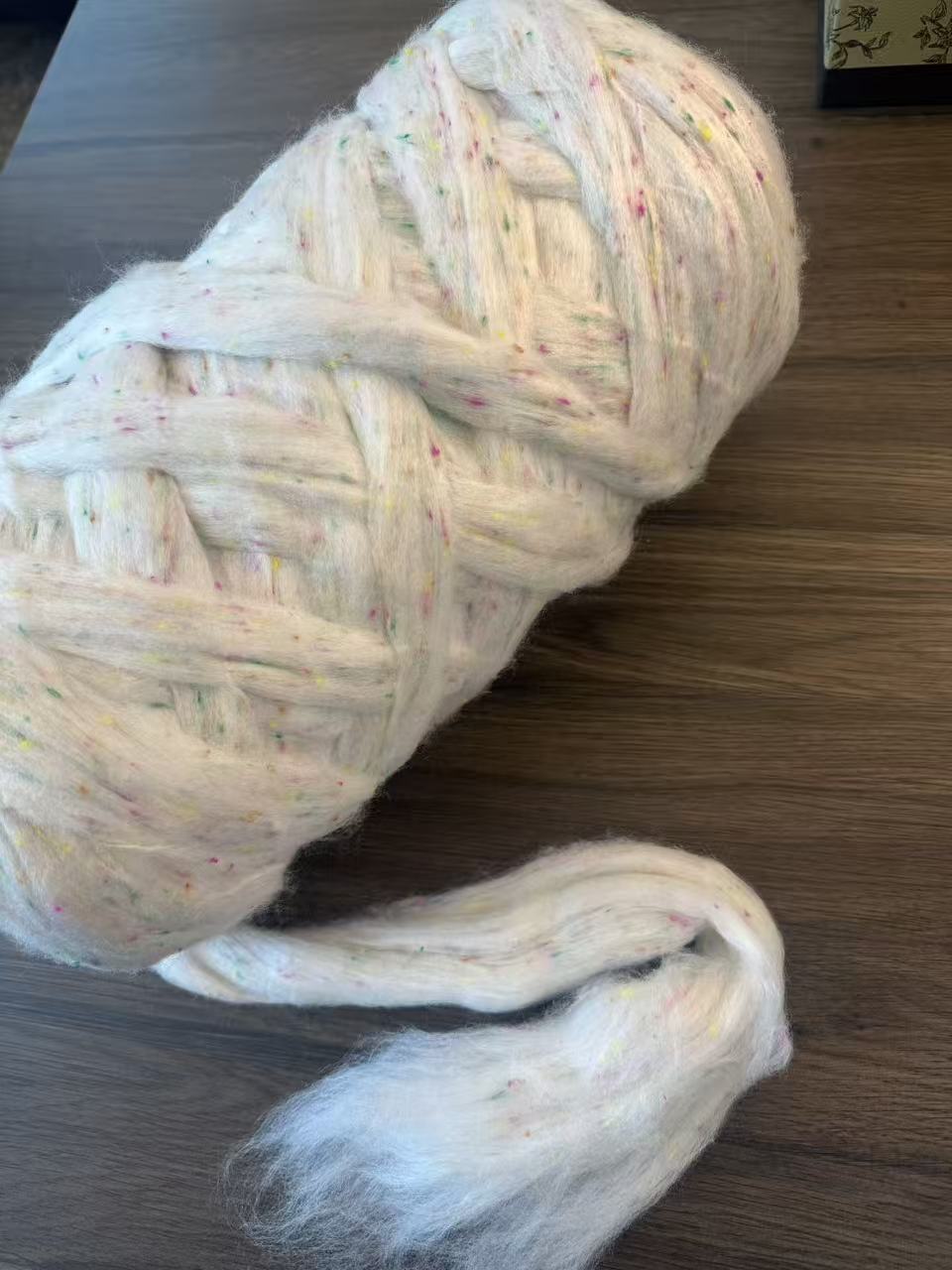

Creating Luxury: Cashmere Blends and the Soft Cashmere Feel

One of the most exciting innovations in modern textiles is the use of nylon in sophisticated blends with natural fibers. While a top cashmere type is prized for its incredible softness and warmth, it can be delicate and costly. By introducing nylon into cashmere blends, we can create a fabric that retains that coveted soft cashmere feel while significantly improving its strength, durability, and affordability. The nylon fiber acts as a strengthening agent, reducing the likelihood of shrinking or stretching and making the final garment easier to care for. This intelligent combination allows consumers to enjoy the luxurious texture and comfort of cashmere in everyday items that are built to last, perfectly merging natural elegance with engineered performance.