An Essential Guide to Nylon 66 Fiber

In the world of advanced materials, few can match the versatility and performance of nylon 66 fiber. As a high-performance synthetic polymer, it serves as a foundational component in countless industries, from automotive manufacturing to high-fashion textiles. This guide will walk you through the essential aspects of this remarkable material, including its production process, core properties, and diverse applications. For engineers, designers, and innovators, understanding this material is key to unlocking new possibilities in product development and pushing the boundaries of what is possible.

A Look into Nylon 66 Production

The journey of creating high-quality fiber begins with the raw material. The Nylon 66 production process starts with a high-performance engineering resin, often supplied in the form of uniform polymer pellets or granules. These small beads represent the pure potential of the final product, engineered for precision and consistency. The pellets are melted down under controlled temperatures and then extruded through a device called a spinneret, which has fine holes that shape the molten polymer into continuous filaments. These filaments are then cooled, stretched, and wound onto bobbins. This stretching process, known as drawing, is crucial as it aligns the polymer molecules and imparts the exceptional strength and tenacity that the PA66 material is known for. The entire process requires uncompromising quality control to ensure the final fiber meets demanding industrial standards.

Understanding Key Polyamide 66 Properties

What makes this fiber so sought after are its unique polyamide 66 properties. Chief among them is its exceptional mechanical strength and tenacity, meaning it can withstand significant stress, wear, and tear without losing its structural integrity. This makes it ideal for heavy-duty applications. Furthermore, nylon 66 exhibits excellent thermal stability, allowing it to perform reliably in high-temperature environments, such as under the hood of a car. It also possesses strong chemical resistance against oils, greases, and many solvents. Despite its ruggedness, a high-quality PA66 fiber can offer extraordinary softness and a silky texture, making it comfortable against the skin while remaining incredibly durable.

Discovering Versatile Nylon 66 Applications

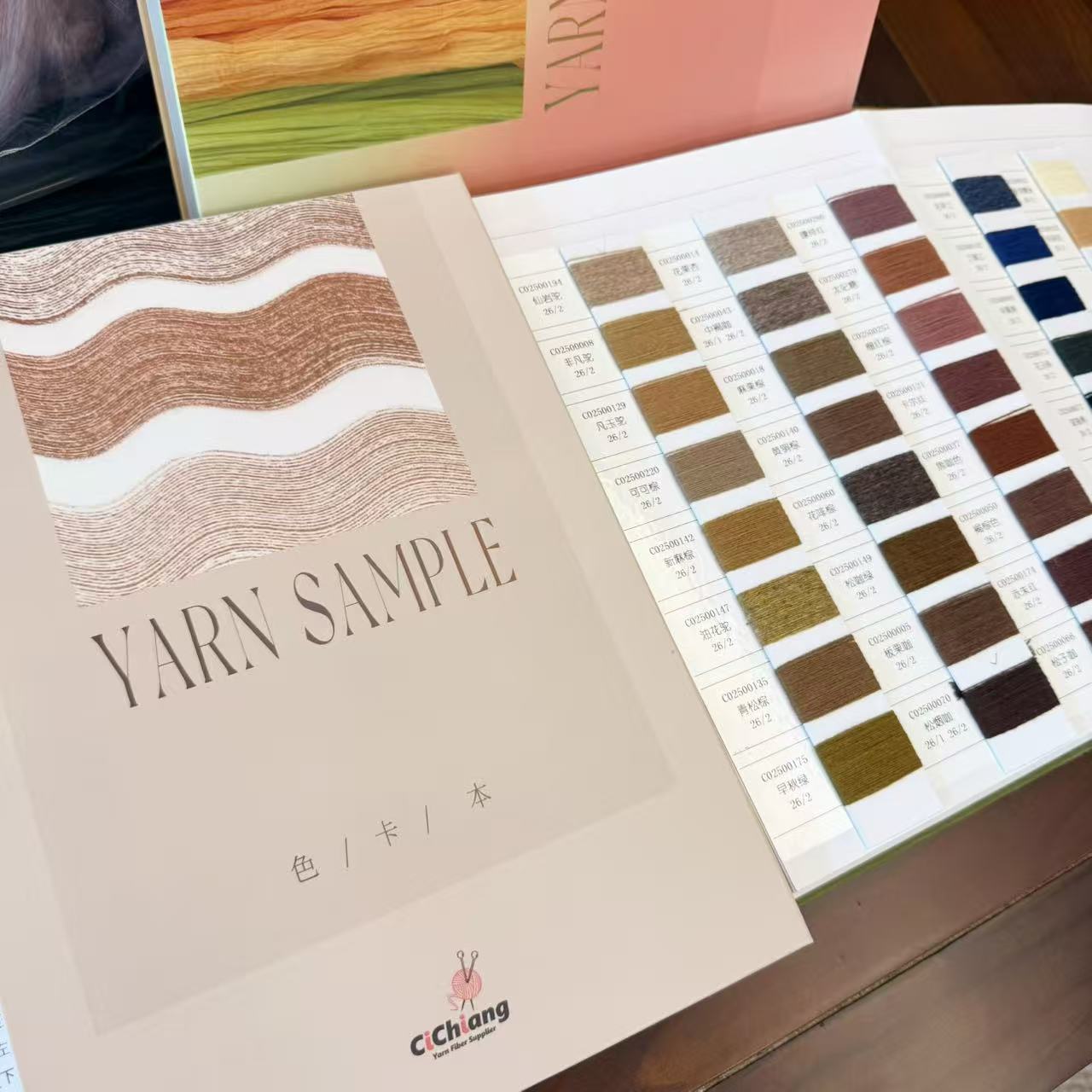

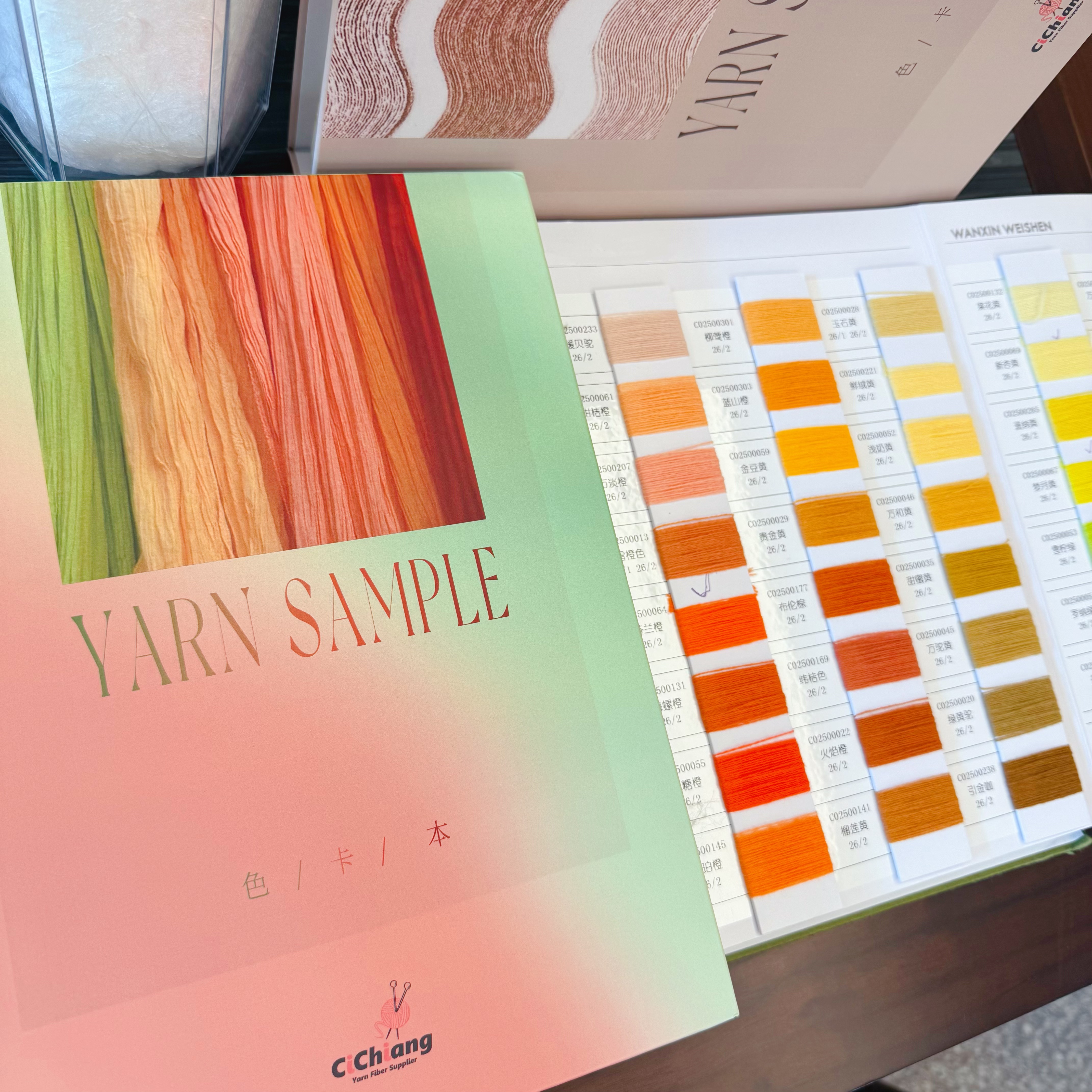

Thanks to its robust profile, there are numerous nylon 66 applications across a wide spectrum of industries. In the automotive sector, its strength and light weight contribute to the manufacturing of durable parts like engine components and under-the-hood systems, promoting fuel efficiency. In the world of textiles, its uses are even more diverse. High-quality Invista textiles are foundational to performance wear, industrial fabrics, and long-lasting carpets that need to resist crushing and matting. In consumer goods, this polymer is used in everything from electronics housings and furniture components to sturdy kitchen tools, ensuring products not only look good but last longer. Its purity and adaptability also mean it can be efficiently dyed, opening up endless creative possibilities for designers.

The Advantage of a Premier Supplier

When sourcing materials for critical applications, the quality of the polymer is paramount. Industry leaders like Invista have perfected the science of producing advanced polymers that deliver consistency and peak performance. High-quality Invista nylon fibers are engineered to meet the strictest standards, providing the reliability that designers and manufacturers depend on. By focusing on innovation from the granular level up, these suppliers ensure that the final nylon 66 fiber provides the exact balance of flexibility, durability, and strength needed for today’s most demanding products. This commitment to excellence makes it possible to turn bold concepts into tangible, high-performing realities.