The world of textiles is constantly evolving, driven by innovations that blend performance, aesthetics, and sustainability. Among the most significant advancements is the development of water-soluble fiber, a revolutionary material that is reshaping how we create and use textiles. These unique fibers are designed to dissolve in water, acting as a temporary structural component during the manufacturing process. This capability opens up a new frontier for designing complex and high-performance synthetic fibers that were once difficult to achieve, enabling unprecedented levels of softness, fineness, and functionality.

Understanding the Science Behind Water-Soluble Fibers

A water-soluble fiber is typically made from a synthetic polymer that breaks down when exposed to water at a specific temperature. One of the most common materials used for this purpose is polyvinyl alcohol, or PVA fiber. In manufacturing, these fibers are spun together with permanent fibers, such as polyester or nylon. They provide temporary support, allowing for the creation of intricate weaves, hollow-core structures, or ultra-fine filaments. Once the fabric is constructed, it is simply washed. The water-soluble materials dissolve away, leaving behind a finished textile with unique properties. This process is a marvel of material science, allowing manufacturers to engineer fabrics with precision and control.

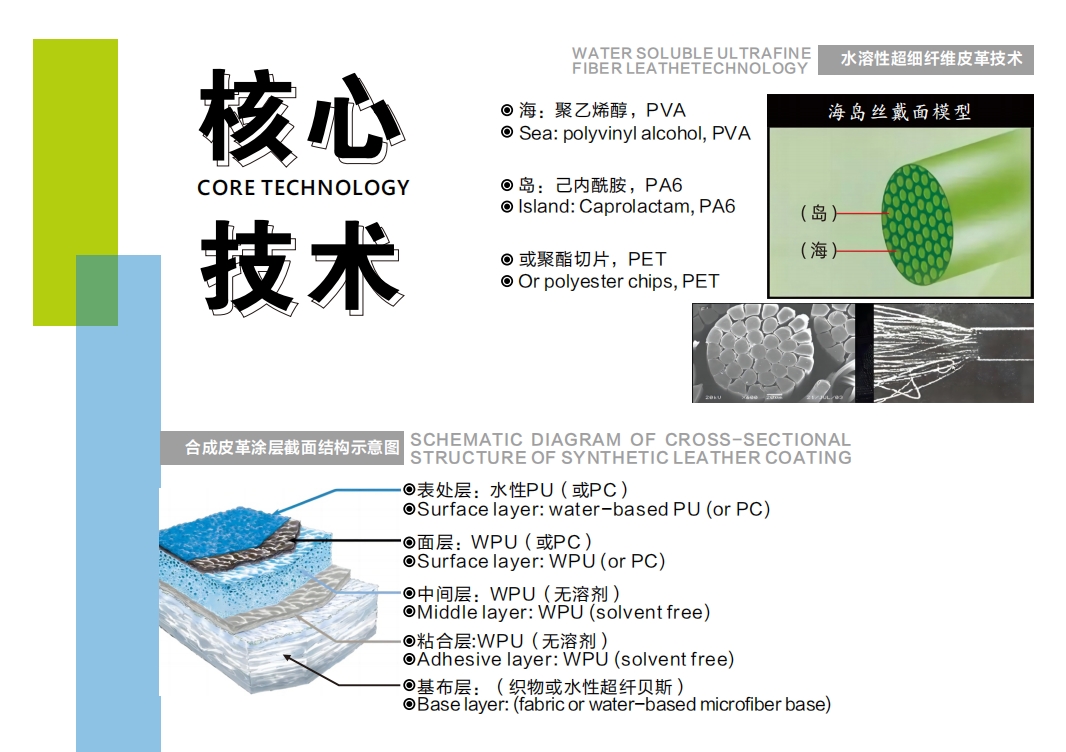

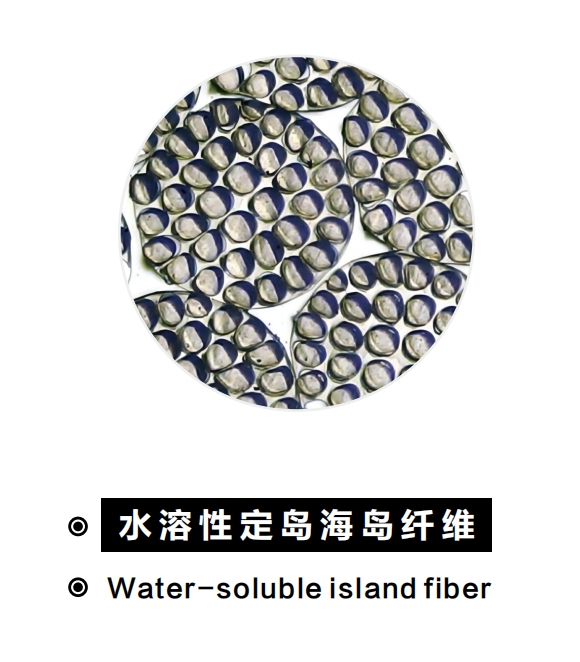

A Prime Example: The Innovative Island Fiber

Perhaps the most brilliant application of this technology is the creation of island fiber. This composite fiber uses a “sea-island” spinning technique where multiple strands of a permanent polymer (the “islands,” which could be a material like PA6 fiber) are embedded within a matrix of water-soluble fiber (the “sea”). After weaving or knitting, the fabric is treated with hot water, causing the surrounding “sea” of PVA fiber to dissolve completely. The result is a yarn composed of incredibly fine microfibers—the “islands” that were left behind. This process allows for the production of fabrics that are exceptionally soft, dense, and lightweight, with a luxurious feel and high-performance characteristics that are ideal for premium apparel and advanced textiles.

Applications and Versatility Across Industries

The potential uses for textiles created with water-soluble fiber are vast and diverse. In the fashion industry, island fiber technology is used to craft high-end apparel with an exquisite hand-feel and elegant drape. Beyond clothing, the resulting microfibers are perfect for producing high-quality cleaning cloths that offer superior absorbency and streak-free performance. The industrial sector also benefits, with applications in advanced filtration systems, medical textiles, and other technical materials where precision and fine filaments are critical. The ability to engineer fabrics at a microscopic level unlocks new possibilities for product development across a wide range of fields.

Sustainability and the Rise of Biodegradable Fibers

Beyond performance, the use of water-soluble materials aligns with a growing demand for sustainable manufacturing practices. By acting as a sacrificial component that is easily removed with water, this technology can reduce processing waste and energy consumption compared to some traditional methods. Furthermore, it supports the push towards more eco-conscious textiles. The principles behind these materials contribute to the development of biodegradable fibers, as the water-soluble components can be designed to break down harmlessly. This fusion of cutting-edge performance and environmental responsibility makes water-soluble fiber a key innovation for a more sustainable future in the textile industry.