The Future of Textiles: Unveiling Water-Soluble Fiber

The world of textiles is constantly evolving, with innovations that push the boundaries of what materials can do. Among the most groundbreaking developments is the emergence of water-soluble fiber, a specialized material designed to dissolve in water under specific conditions. This remarkable technology is not just a novelty; it is a transformative tool that enables the creation of incredibly fine fabrics and advanced materials that were previously impossible to produce. By integrating these dissolvable components into complex synthetic fibers, manufacturers can achieve new levels of softness, performance, and design precision, heralding a new era for both fashion and industrial applications.

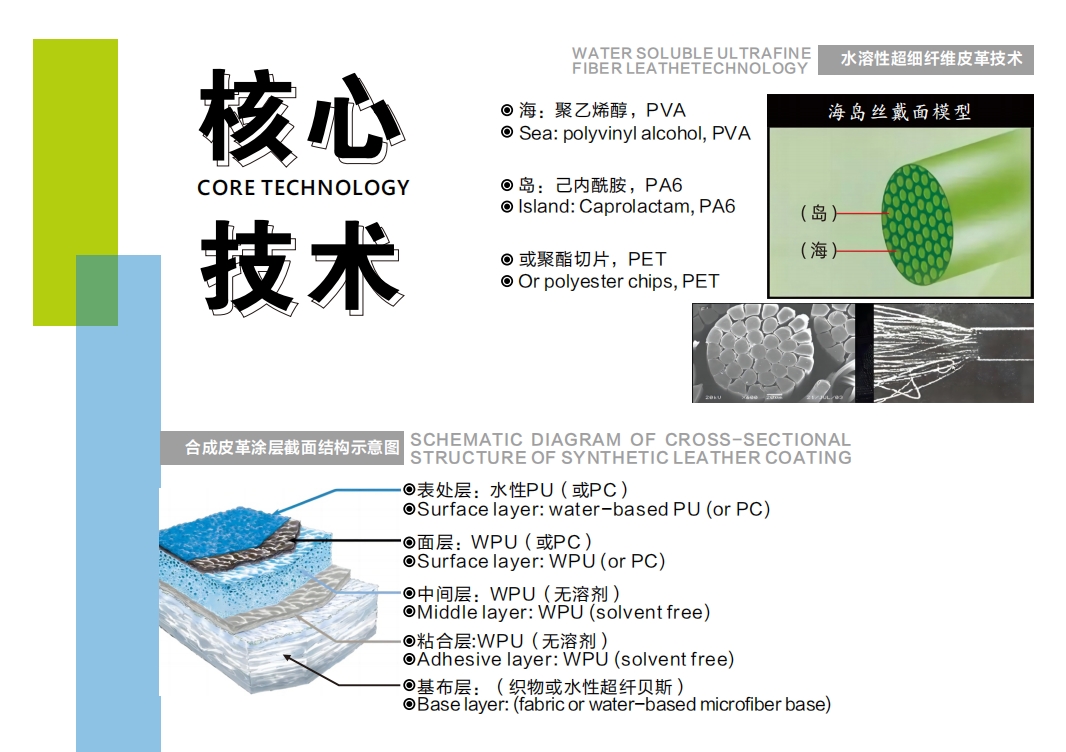

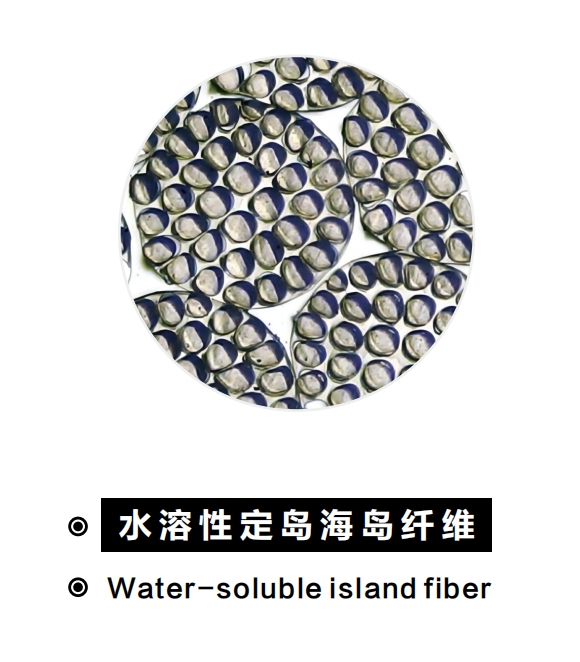

The Technology of 'Island-in-the-Sea' Composites

At the heart of this innovation is a sophisticated composite spinning technique, often referred to as the 'island-in-the-sea' method. In this process, two different polymers are extruded together to form a single filament. One polymer, the 'island,' constitutes the core ultra-fine fiber that will remain. The other polymer, the 'sea,' is the water-soluble component that surrounds and holds the islands together. A common material used for the dissolvable 'sea' is PVA fiber (Polyvinyl Alcohol), which is known for its ability to dissolve cleanly in water. The 'island' components can be various polymers, such as PA6 fiber or polyester, chosen for their desired final properties. Once the fabric is woven or knitted, it is washed in hot water. The PVA fiber dissolves away, leaving behind a web of extremely fine, separated microfibers. This island fiber technology allows for the production of fibers far thinner than a human hair, creating textiles with unparalleled softness and a luxurious drape.

Versatile Applications Across Industries

The unique properties of fabrics made using this method open up a vast range of applications. In the fashion industry, these ultra-fine fibers are used to create high-end faux suedes, lightweight performance wear, and textiles with a silk-like feel and superior comfort. The resulting material is not only soft but also dense and durable, making it ideal for luxury apparel and accessories. Beyond clothing, these advanced synthetic fibers are crucial in technical fields. They are used to manufacture high-performance cleaning cloths that can trap dust and absorb liquids effectively, as well as advanced filtration media for air and liquids. The precision of the island fiber structure allows for the creation of filters with very specific pore sizes, making them valuable in medical and industrial settings.

Pioneering Sustainable and Clean Manufacturing

The use of water-soluble materials in textile production represents a significant step towards more sustainable manufacturing practices. Traditionally, creating fine fibers often involved harsh chemical solvents that could be harmful to the environment. The water-based dissolution process, in contrast, is significantly cleaner. Furthermore, the dissolved polymer, such as PVA, can often be recovered from the water and recycled for use in subsequent production runs, creating a closed-loop system that minimizes waste. This aligns with a growing global demand for eco-conscious products and biodegradable fibers. By providing a method that is both highly effective and environmentally responsible, water-soluble fiber technology offers a compelling solution for companies looking to innovate while reducing their ecological footprint, proving that high performance and sustainability can go hand in hand.