The textile industry is constantly evolving, driven by innovations that redefine functionality, comfort, and sustainability. A key player in this transformation is the water-soluble fiber, a remarkable material that acts as a temporary tool to create incredibly complex and high-performance fabrics. While not always present in the final product, these fibers are a critical component in manufacturing processes, enabling the production of textiles that were once thought impossible. Their ability to disappear with a simple water treatment unlocks a new level of precision and design freedom.

The Technology Behind Water-Soluble Fibers

At its core, a water-soluble fiber is a type of synthetic fiber specifically engineered to dissolve in water, often at a specific temperature. One of the most common examples is PVA fiber (Polyvinyl Alcohol fiber), which is spun into yarn just like traditional fibers. Manufacturers then weave or knit this PVA yarn alongside other permanent fibers, such as polyester or nylon. Once the fabric construction is complete, it is washed. The PVA fiber dissolves completely, leaving behind a fabric with unique properties, such as incredible softness, an open and lightweight structure, or intricate hollow patterns. These water-soluble materials serve as a temporary scaffold, providing support during manufacturing before seamlessly vanishing.

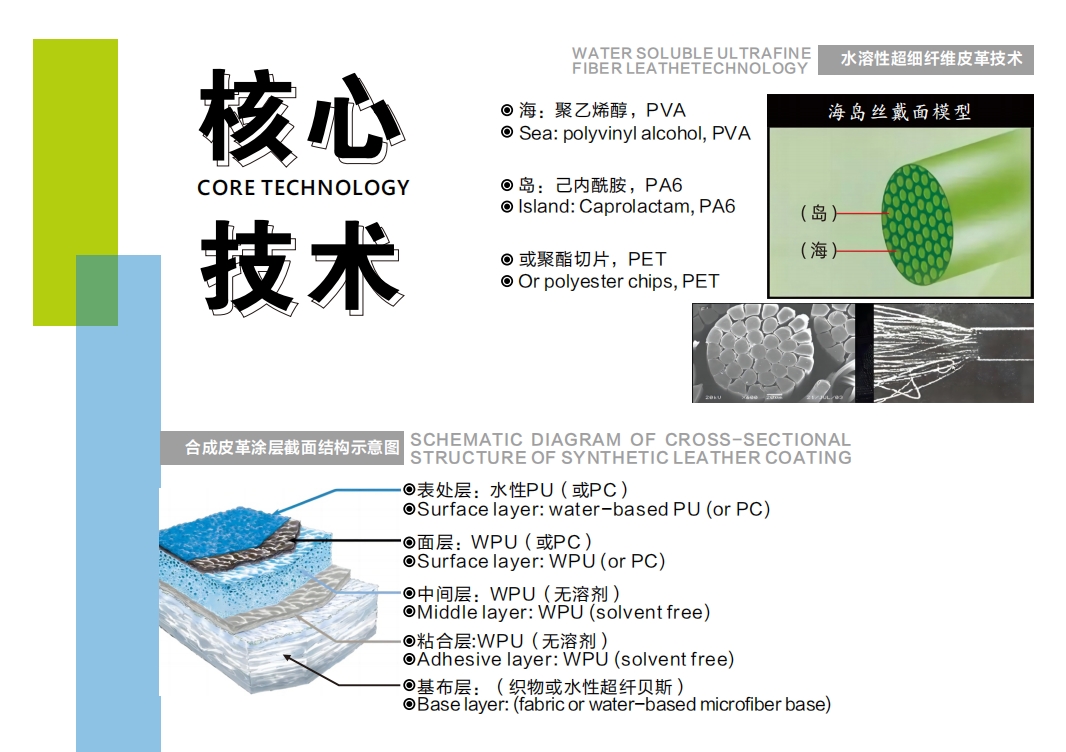

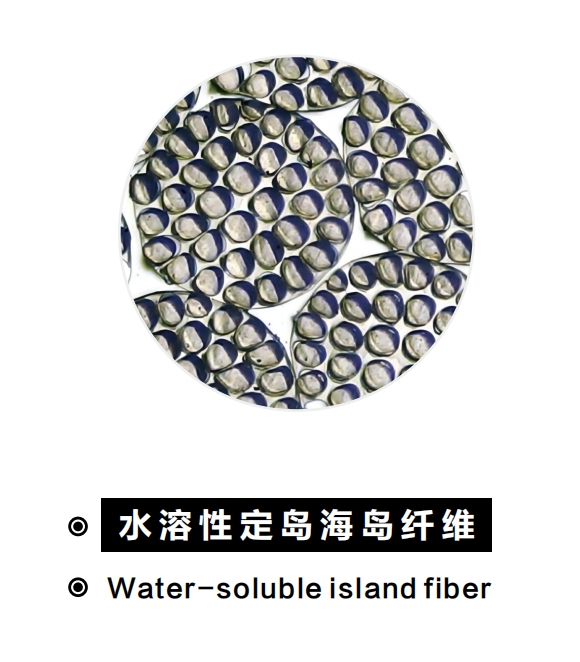

Innovation in Action: The Sea-Island Structure

A groundbreaking application of this technology is the creation of island fiber. This advanced composite fiber features a unique cross-section where multiple fine filaments (the "islands") are embedded within a soluble polymer matrix (the "sea"). The "island" component is typically a high-performance polymer like PA6 fiber or polyester, chosen for its durability and desired final characteristics. During production, this composite fiber is handled as a single, larger filament, making it easier to spin and weave. After the fabric is constructed, the water-soluble "sea" component is dissolved, releasing the ultra-fine "island" microfibers. This process allows for the creation of fabrics with an exceptionally soft touch, high density, and superior performance without the challenges of trying to spin microfiber directly.

Applications and Sustainable Benefits

The versatility of water-soluble fiber technology opens doors to a vast range of applications. It is instrumental in producing high-end artificial suede and leather, high-density waterproof textiles, and advanced filtration media. Beyond performance, this method offers significant environmental advantages. The process often reduces the need for harsh chemical treatments, and the development of biodegradable fibers for the soluble component further enhances its eco-friendly credentials. This innovative approach allows for the creation of sophisticated materials with purpose-driven textures, such as engineered curly fibers for superior insulation or feather-light recycled fills for sustainable outerwear, creating a future where high performance and environmental responsibility coexist seamlessly in our fabrics.