Unveiling the Innovation of Water-Soluble Fiber

In the dynamic world of material science, few innovations have been as transformative as the development of water-soluble fiber. This remarkable material is redefining the possibilities within textiles, manufacturing, and environmental sustainability. Unlike traditional synthetic fibers that are designed for permanence, these advanced fibers are engineered to dissolve in water under specific conditions, opening up a new frontier for product design and functionality. This unique characteristic allows for the creation of incredibly fine, lightweight, and complex textile structures that were previously impossible to achieve, marking a significant leap forward for high-performance water-soluble materials.

Understanding the Science Behind Dissolvable Textiles

A water-soluble fiber is a type of polymer that disappears when immersed in water, typically at a controlled temperature. The most common material used for this purpose is polyvinyl alcohol, widely known as PVA fiber. This fiber acts as a temporary scaffold or a carrier component in a composite yarn. During the manufacturing process, it is spun together with a non-soluble fiber. Once the fabric is woven or the product is formed, it is washed in hot water. The PVA fiber dissolves completely, leaving behind a fabric with unique properties, such as exceptional softness, a hollow structure, or an incredibly low density. This process demonstrates the clever application of chemistry to achieve unparalleled textile engineering feats.

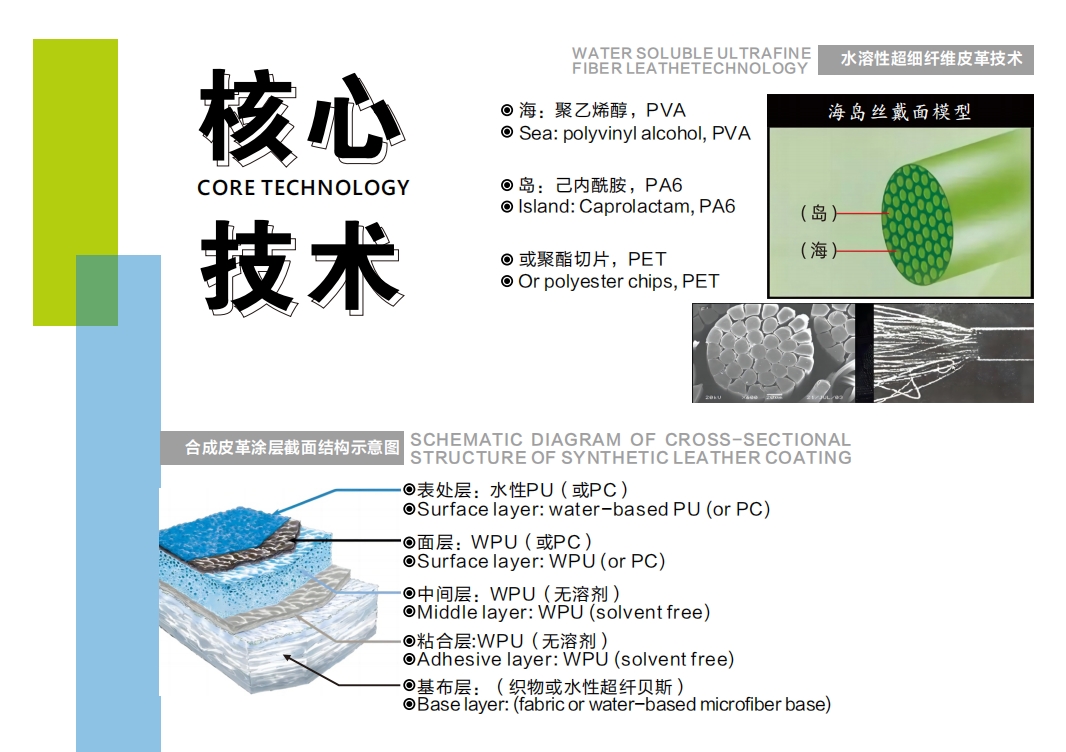

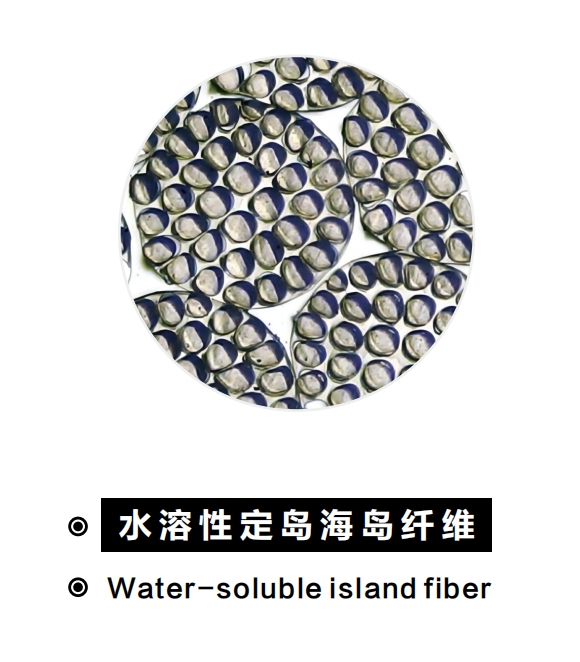

A Closer Look at Island Fiber Technology

One of the most exciting applications of this technology is in the creation of island fiber. This composite fiber features a unique structure where multiple strands of an insoluble polymer (the 'islands,' often made of materials like polyester or PA6 fiber) are embedded within a matrix of a water-soluble polymer (the 'sea'). When the sea component is dissolved, it releases the islands as ultra-fine microfibers, often much finer than can be produced through conventional spinning methods. The result is a material with a luxurious, suede-like feel, superior drapability, and enhanced softness. This island fiber technology is a perfect example of how dissolving a component can add immense value and create a high-performance final product.

Diverse Applications and Strategic Advantages

The applications for water-soluble fiber are vast and continue to grow. In the fashion industry, it is used to create lightweight, voluminous fabrics and delicate imitation silks and leathers. Its ability to create hollow-core fibers also leads to textiles with excellent thermal insulation. Beyond apparel, these fibers are crucial in specialized industrial applications, including the manufacturing of high-precision polishing cloths and advanced filtration media where ultra-fine fibers are essential. The primary advantage is the ability to engineer the final properties of a fabric with incredible precision, all by simply washing away a temporary structural component.

The Sustainable Future with Biodegradable Fibers

Beyond performance, water-soluble technology offers significant environmental benefits. The process uses water as a solvent, avoiding the harsh chemicals often required in other textile treatments. Furthermore, this innovation aligns with the growing demand for sustainable production and biodegradable fibers. As the industry moves towards a circular economy, materials that can be easily separated or that have a minimized environmental footprint are crucial. Water-soluble materials contribute to this goal by enabling more efficient manufacturing processes and supporting the development of textiles that are both high-performing and environmentally conscious, paving the way for the next generation of smart and sustainable products.