When searching for a high-performance material that masterfully blends strength, durability, and versatility, the answer often lies in nylon 66 fiber. This synthetic polymer has become a cornerstone in countless industries due to its exceptional characteristics. This guide is designed to walk you through everything you need to know about this remarkable material, from its fundamental properties to its diverse applications, helping you understand how to leverage it for your specific needs.

What Exactly Is Nylon 66?

Nylon 66, also known as PA66, is a type of polyamide made from two monomers: hexamethylenediamine and adipic acid. The '66' in its name refers to the fact that both the diamine and the diacid monomers have 6 carbon atoms each. This specific chemical structure results in a semi-crystalline polymer with a highly ordered molecular arrangement, which is the secret behind its superior mechanical strength and thermal stability. As a leading PA66 material, its unique molecular makeup is directly responsible for the impressive polyamide 66 properties that make it a preferred choice for engineers and product designers. Its inherent resistance to wear and friction sets it apart from other polymers.

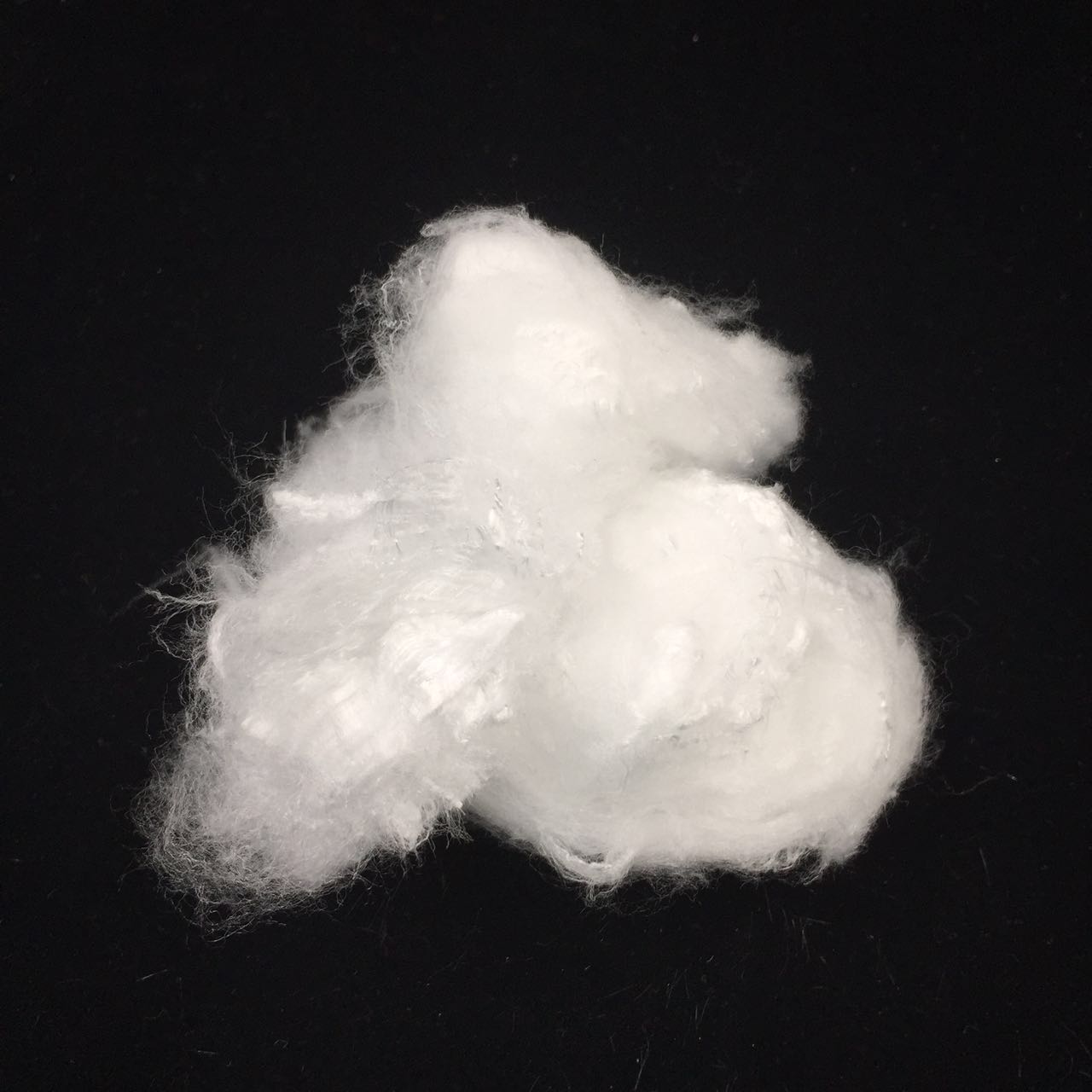

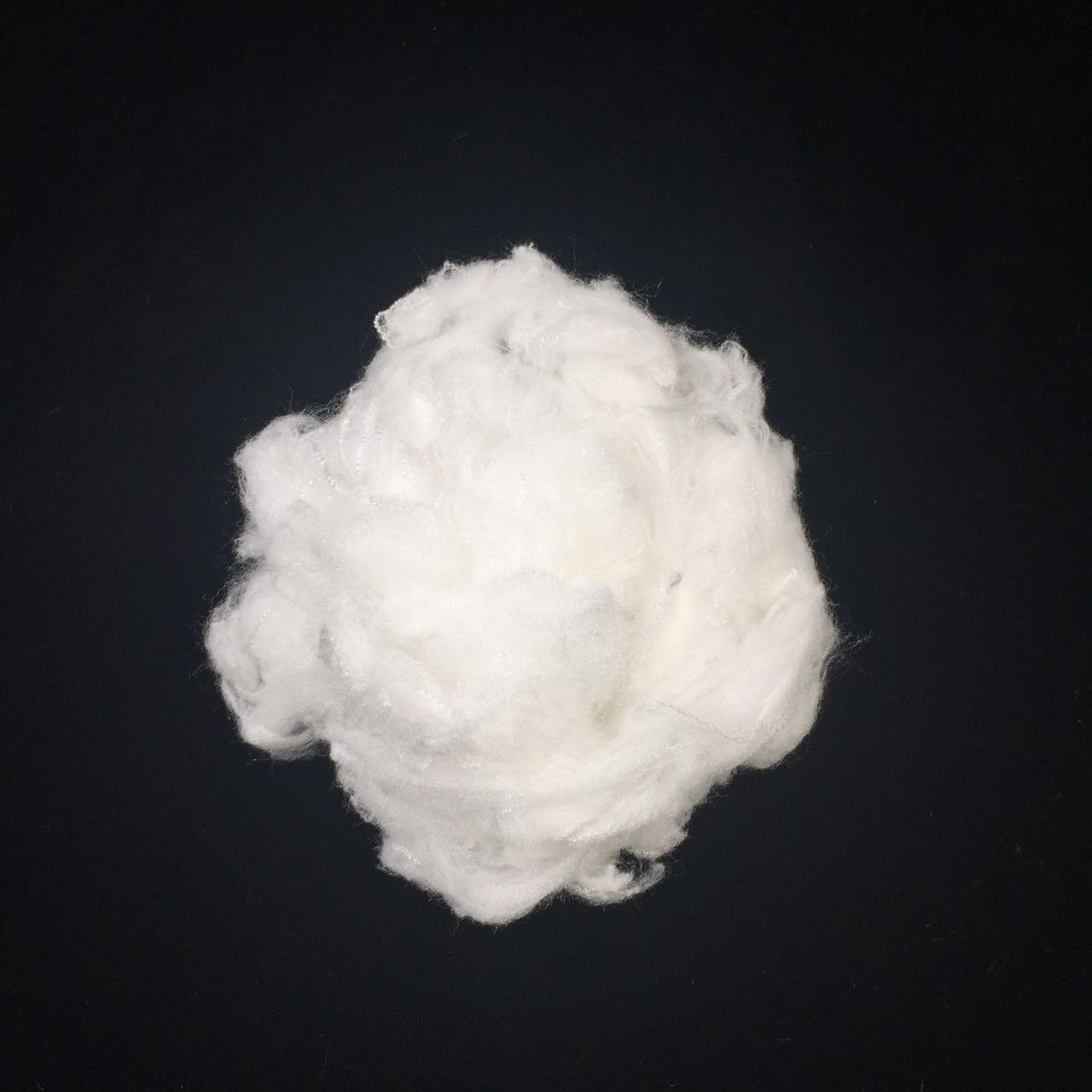

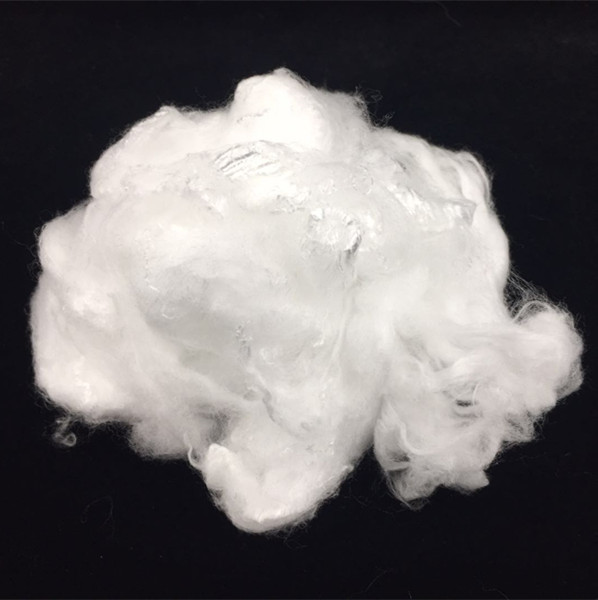

A Glimpse into the Nylon 66 Production Process

The journey of Nylon 66 production begins with a process called condensation polymerization. The two core monomers are combined to form a nylon salt, which is then heated under pressure in a reactor. This process removes water and links the monomers into long, repeating polymer chains. The resulting molten polymer is then extruded through a device called a spinneret, which has tiny holes, to form continuous filaments. These filaments are cooled, stretched, and wound onto bobbins. This stretching process, known as drawing, aligns the polymer chains and is crucial for developing the fiber's strength and elasticity. Industry leaders like Invista have refined this process to produce high-quality Invista nylon fibers with exceptional consistency and performance.

Key Properties and Advantages

The popularity of Nylon 66 is built on a foundation of elite material characteristics. The polyamide 66 properties include a high melting point (around 265°C or 509°F), making it suitable for high-temperature applications. It exhibits excellent tensile strength and stiffness, allowing it to withstand significant force without breaking or deforming. Furthermore, this PA66 material is highly resistant to abrasion, making it ideal for products that experience a lot of friction, such as carpets, upholstery, and industrial bearings. It also boasts good chemical resistance, particularly to oils and fuels, and has a great elastic recovery, meaning it can stretch and return to its original shape.

Discovering the Diverse Nylon 66 Applications

The versatility of this polymer leads to a vast array of nylon 66 applications across numerous sectors. In the textile industry, it is used to create durable carpets, high-performance activewear, hosiery, and rugged luggage. High-quality Invista textiles, for example, leverage these fibers to deliver products with superior longevity and comfort. Beyond fabrics, its mechanical strength makes it a staple in the automotive industry for parts like engine covers, air intake manifolds, and gears. It is also found in electrical components as an insulator, in industrial machinery for durable parts, and in consumer goods ranging from zip ties to kitchen utensils. The lightweight yet robust nature of the PA66 fiber makes it a powerful tool for innovation.

How to Choose the Right Material for Your Project

Selecting the correct PA66 fiber requires a clear understanding of your project’s demands. Consider the tenacity, or strength, required. For applications like ropes or safety belts, a high-tenacity fiber is essential. For apparel, you might prioritize a finer denier for a softer feel. It is also critical to source your material from a reputable manufacturer that guarantees quality control and batch-to-batch consistency. Working with a trusted supplier ensures that the nylon 66 fiber you receive meets the precise specifications needed to create a reliable and high-performing end product, unlocking its full potential.